How was REVICO founded?

The Cognac eau de vie produced in Charente comes from the double distillation of Charente wines. Like all distillation processes, still distillation generates vinasses: dealcoholized white wine.

Over the years, distillers in the Cognac sector become aware of the impact that the discharge of vinasse can have on the natural environment. They decide to create a decontamination plant exclusively dedicated to the treatment of this effluent.

REVICO is therefore born from the common will of the players in the sector to offer the best technology for processing vinasses.

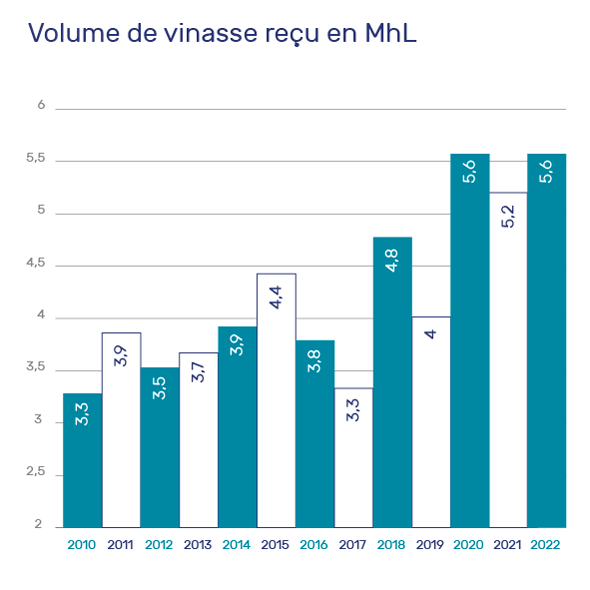

REVICO is always committed to ensuring pollution control and since the beginning of the 2020s, the company receives nearly 6 million hectolitres of vinasse annually, i.e. 55% of the total volume of Charente vinasse produced.

The Cognac sector in figures

The Cognac vineyard represents more than 10% of the total area of French vineyards and produces nearly 25% of the wine intended mainly for distillation. This represents 90,000 ha allocated to the production of Cognac, for 10.4 million hectoliters of wine produced in 2022 [BNIC 2022 data].

To fully understand the volumes represented at each stage of Cognac production, let’s take a look at the figures for the 2022 harvest.

+ 10 M hl

10,4 million hectoliters (M hl) of Cognac white wines harvested

1000000 hl

1 million hectolitres of pure alcohol distilled

9 M hl

9 M hl theoretical vinasses generated

55 %

55% of the total vinasses decontaminated by REVICO.

REVICO commits to the environment

At the Saint-Laurent de Cognac plant, melliferous plants have been sown at the foot of the methanisers to encourage biodiversity. Evidence of REVICO’s good environmental health: an apiary was set up on the site in 2017.

Today, 5 hives thrive on the site, proving that bees can live in an industrial environment.

ISO 14001

Certification

Since 2019, REVICO has been ISO 14001 certified for its environmental management. To obtain this certification, the company has committed to a process of progress aimed at limiting the environmental impact of its activities. ISO 14001 is an international standard that also allows a projection into the future by planning actions to improve and optimize processes.

The company is ISO 14001 certified for the following activities:

- decontamination and recovery of distillation by-products

- production of bio-sourced calcium tartrate

- methanisation

- production of renewable electricity.

REVICO Énergies Vertes, the branch dedicated to renewable energy

Thanks to the methanisation process, which recovers organic matter from vinasse, REVICO is helping to decontaminate the entire Cognac area. Methanisation transforms the organic compounds in vinasse into biogas. In 2008, the REVICO – Énergies Vertes branch was set up to convert the biogas into electricity and heat using a cogeneration plant.

Revico's partners

REVICO has been supporting the Cognac industry for over 50 years. The company exists thanks to a common will to reduce the impacts related to the Cognac activities on the environment. It is also thanks to the lasting trust of institutions and shareholders that the company can develop and thus recover ever more organic waste. Also, the entire REVICO team thanks its partners and shareholders for their renewed confidence.

How does REVICO work?

REVICO is a unique company in France. 40 employees with complementary skills ensure the proper functioning of the plant’s units. Drivers, production agents, maintenance technicians, quality and laboratory technicians, design engineers and site engineers.

Thanks to the shared investment effort of the entire Cognac sector, the REVICO company has developed a complete and exclusive industrial process. Its plant is located in Saint-Laurent-de-Cognac.