What is vinasse?

After harvesting the white grape varieties grown in the Cognac region, the grape must is vinified. The must is the juice of the freshly pressed fruit, separated from the skins, seeds and stalks that make up the marc.

This wine is then distilled twice in Charentais stills, leading to the production of an exceptional eau-de-vie which, after aging in barrels, becomes Cognac.

At the same time, distillation generates a liquid by-product, the so-called vinasse charentaise, which is a de-alcoholised white wine rich in organic matter. For a wine containing 10% alcohol, vinasse represents 86% of the wine’s initial volume. It is important to distinguish between vinasse de vin obtained during the first distillation and vinasse de bonne chauffe, which comes from the second distillation. The mixture of these two types of vinasses is called vinasse charentaise.

The processing of vinasse charentaise

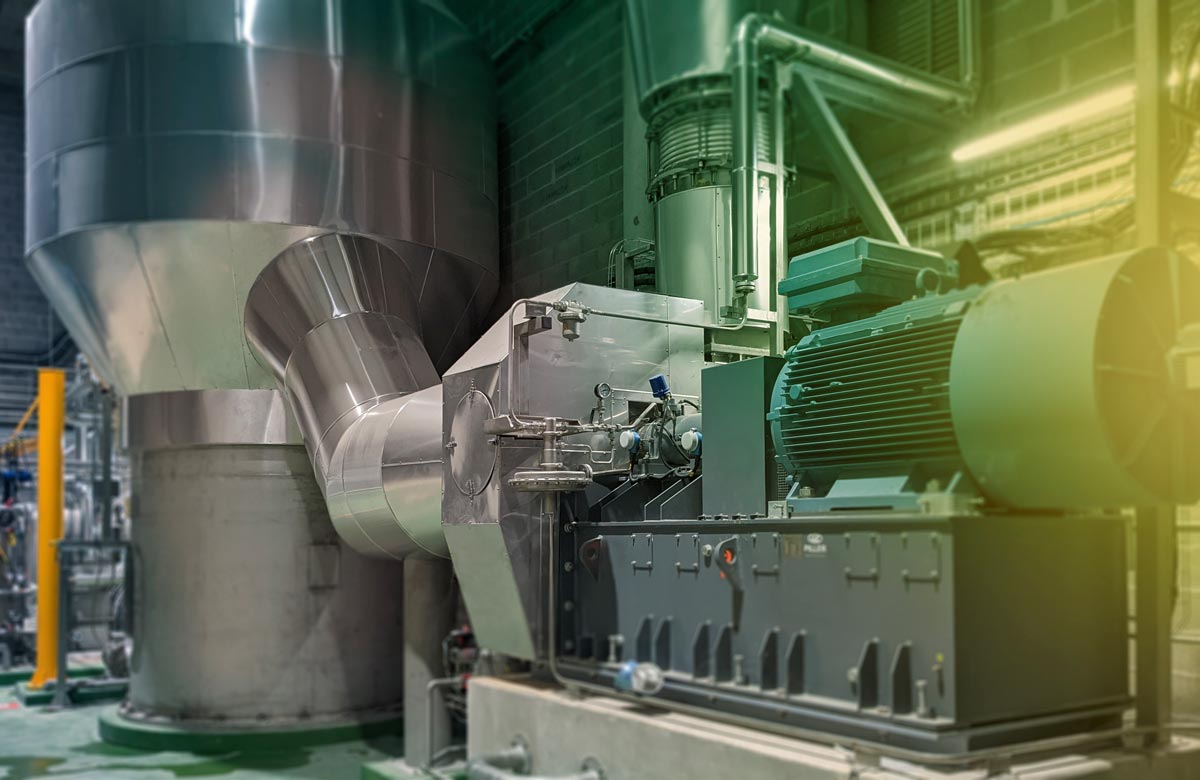

The pre-treatment step by concentrating the vinasses

The vinasse that arrives at the REVICO plants is a liquid charged with the natural constituents of wine (except alcohol). The concentration step is an enrichment of these molecules. This evaporation carried out in a thermal evaporator makes it possible to separate the vinasse into two liquid phases:

The condensate contains little organic matter, which goes directly to aerobic biological processing (step 4).

The concentrate, which is the phase enriched with all the molecules of the wine and is sent to the tartaric acid extraction process.

Did you know?

Condensate is a transparent liquid charged with volatile organic compounds. Transparency in this case is no guarantee of the absence of contamination. That’s why condensate must be treated before being released.

The tartaric acid extraction step

The concentrate – the vinasse enriched with organic matter – is brought into contact with calcium carbonate, allowing calcium tartrate crystals to form. Calcium tartrate, separated from the rest of the concentrated vinasse by filtration, is then dried to be sold. It comes in the form of a beige powder. In refineries, this calcium tartrate is then re-transformed into tartaric acid. The main uses for tartaric acid are in oenology, food industry, pharmaceuticals and plaster industry.

Did you know?

In the middle of the 19th century, Louis Pasteur began his scientific studies at the University of Lille by studying tartaric acid crystals in wine. Louis Pasteur wondered about this molecule whose optical characteristics are surprising and which can deflect light to the right or left. He thus laid the foundations of the asymmetry of certain organic molecules.

The methanisation step

The extraction of tartaric acid enables a specific molecule contained in the vinasse to be retained, but there are still many organic constituents that need to be eliminated.

Methanisation (or anaerobic digestion) transforms these organic residues into biogas, thanks to the action of bacterial biomass working in the absence of oxygen. After an average residence time of 3 weeks in the reactors, the purification performance in terms of eliminating organic elements reaches 95%.

Did you know?

1 m3 of biogas produced by REVICO produces as much energy as 1 liter of ethanol or 0.7 liters of gasoline.

REVICO produces up to 25,000 m3 per day of biogas.

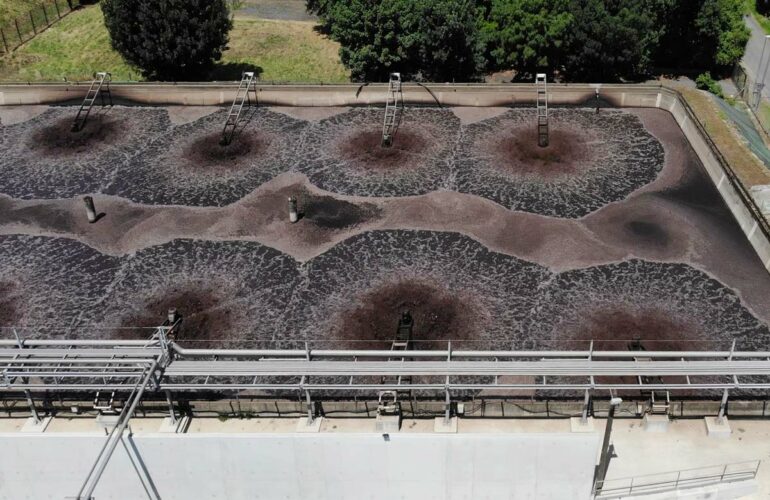

Aerobic biological treatment step

It is thanks to the action of an aerobic bacterial flora, i.e., working with oxygen, that the last organic residues are decontaminated. The combination of anaerobic digestion and aerobic biological treatment eliminates 99% of the organic contaminants in the vinasses before it is released into the natural environment.

Aerobic biological treatment takes place in 2 types of installation: a 10,000 m³ activated sludge tank and a vegetated biological filter.

Did you know?

REVICO also treats, in smaller volumes, washing water from wine-making cellars, whisky stillage, rum stillage and any other stillage produced during the manufacture of spirits.

Additional treatment

and control

After a final treatment by static decantation and lagooning, the effluent is released into the natural environment. REVICO’s laboratory analyses the quality of the treated effluent on a daily basis.

This control phase ensures that the effluent is discharged into the natural environment in compliance with the regulatory framework set by the authorities.